The world is looking for astonishing merchandise with supreme-quality fabric printing. The list of different types of fabrics is quite long, with various results in terms of quality and durability. The result of your wishes is totally dependent on the fabric and pattern you choose.

There are various textile printing methods that are used to create and embed prints and designs on the fabric. It’s never an easy choice until you do your homework. Let’s take a look into the various types of printing on fabric to make your decision easy.

Dye Sublimation Printing

Dye sublimation is also called digital sublimation. It is printing technology that applies an image to the fabric by using heat. This is a special process for decorating clothing products or giving them a unique appearance.

Pros

- High-quality prints.

- Durability.

- Vibrant colors.

Cons

- Only limited to bright colors; no printing on black or dark surfaces.

Screen Printing

Custom screen printing is a technical process carried out only by professionals. The ink is pushed by the squeegee in various shapes and patterns on the screen that go through the fabric, creating the same shape as desired. Screen frames create and print the pattern through each color.

Thus, in cases of a plethora of colors, complex designs are not supported by screen printing. Instead, simple colors give a good effect to the screen printing.

Additionally, there is a fixed price for each screen frame. If you want a lower cost on each product, it is best to place bulk orders, more than at least 500 pieces.

Pros

- Suitable for Simple Designs.

- Flexible in terms of printing materials.

- Long Lasting.

Cons

- Complicated setup time.

- High print volume is necessary.

- Color limitations.

Water-Based Printing

Fabric absorbs the water ink. It is the same when you are dyeing the fabric because the main element is water itself. It’s extremely comfortable and smooth. Thus, it is considered to be one of the best types of printing on fabric and widely used for major printing areas.

Pros

- Compatible with all fabrics of light color, like cotton, linen, etc.

- Long-lasting colors.

- Able to cope with many washings.

- Highly affordable.

Cons:

- Pattern coverage is not of good standard.

- Printing over dark fabric is highly unsuggested.

Printing with Plastisol

Unabsorbable dyes are used by the fabric in this type of printing. This allows the print to feel attached to the surface of the fabric. There is a nice coverage of this method on the printing patterns.

It is ideal for both light and dark colored fabrics. The patterns have high durability with good ink. This costs more as it is a complex process.

Pros

- Suited more with a small area print like logos.

Cons

- The texture is quite hard because of the thickness.

Digital Printing

One of the ways of printing on fabric is digital printing. Another name for this type is Direct Ink-Jet printing. The process is as simple as printing the ink directly on the paper in your office.

The printing requires the dye to be sprayed directly on the textile for achieving the desired pattern. The pattern is to be opened on the computer after the insertion of fabric. All good to go for printing!

Pros

- Allows you to create different kinds of prints on fabric with multiple colors.

- Flexibility to add different effects to the print.

- The fabric is very smooth and easy to breathe.

Cons

- Small paper size.

- Limitations of toner-based colors.

- Digital inks fade in sunlight.

Block Printing

This is an old method, still in use, where the fabric was designed on a piece of block. Dipped into the ink off and on, the block is then pressed against the fabric to imprint the design on the block. The process is repeated with different colors until the whole pattern is ready.

Pros

- Easy to do at home as well.

Cons

- It is not much preferred for commercial use considering the speed of effort required in this type of printing.

Roller Printing

First, the roller is put in a dye on its surface, and the patterns are then engraved on it. The dye is removed from the unengraved part using a scraper. The unengraved part allows the dye to transfer to the fabric after the roller is pressed over it. A pattern is elegantly formed.

Only one type of color is printed by each roller. One may print multiple colors if a bulk of rollers are added to the printing machine. In order to attain delicate patterns, thin lines must be drawn on the rollers. The speed of the machine goes up to 70-100 meters in one minute.

There is no hassle in printing millions of yards of fabric once the roller is ready and the machine is set. This is a super bulk production method. This method costs a lot of time and money, which is why it is considered uneconomical for small-scale orders.

Pros

- It is quick.

- Efficient.

Cons

- Initial setup is expensive.

- Repetitive designs are limited.

Electrostatic Printing

An electrostatic charge is used to pull the powder dyes or ink towards the fabric. The design is put between fabric and powder, whereas the charge is placed at the back of the fabric.

The screen is flashed with the mixture of dye and resin when the fabric goes through the electrostatic field. This allows the pattern to be created smoothly and beautifully.

Pros

- Fast printing speed.

- Low ink consumption.

- Good print quality.

- Good transfer efficiency.

Cons

- It clogs due to small orifice diameters.

Blotch Printing

This allows for the printing of the design’s background color rather than dyeing. This allows the fabric to remain white from the other side. The white fabric has both colors of the background with the required design in one go.

Pros

- Fast Process.

- It takes less time to produce a large number of materials.

Cons

- Often fails to cover large background color areas of the print with full-depth of colors.

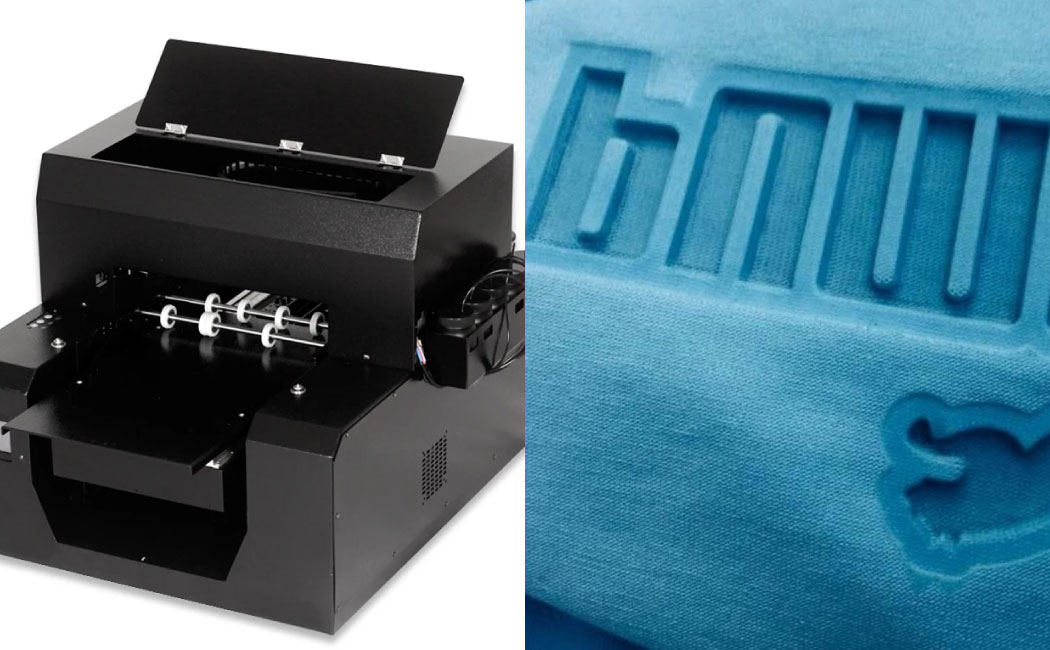

3D Concave-convex Printing

You will observe a powerful 3D effect with this technique. Usually, it is recommended for the printing of logos and texts. Two ways can be used for concave convex printing.

For creating the pattern, screen printing is used. A steam with high temperature is used for producing the effect of concave convex. Before this, the shrinking of the pattern is to be done once a specific liquid is printed at the borders of the pattern.

Another way is to use silica gel on the fabric. A three-dimensional pattern with heat is formed when fabric is put for printing. The special design is used with mold opening. A partial fee is needed for making the plate.

Flock Printing

First, a pattern is formed through screen printing. A proper voltage is set for the electrostatic field to sprinkle the flocking powder on the pattern. For the adhesive to print properly, it needs to be blown repeatedly to dry on time.

Pros

- There is a strong sense of three-dimensional effect in patterns of flock printing.

Cons

- Highly costly and takes abundant time.

- It is at risk of fading with frequent washing.

Which Printing Method is the Best?

Several printing methods, like the one above mentioned, are acknowledged for their abilities to make a garment market-ready. There has been a debate over sublimation vs. screen printing since both methods are commonly adhered to and known for the outstanding results.

However, all the other ways of printing on fabric have been proven effective, depending on the type of cloth. You can choose the textile printing methods according to specific designs, garments, and personal choices.

Conclusion

The textile industry adheres to various fabric printing techniques that are beneficial in applying the most stunning prints on garments. But of course, there is no garment or thread in the world without certain flaws.

For my audience, including brands, manufacturing companies, potential buyers of clothes, and people with a thirst for knowledge about fabric printing, I have mentioned 10 ways of printing on fabric.

I have also mentioned the pros and cons of each method for you to get a better idea. Moreover, this guide will help you make an informed decision about choosing your preferred fabric printing techniques.