Manufacturing clothes in a particular way using different techniques and methods is an art. Suppose you have designs, patterns, and colors ready to be printed on the clothes but don’t know how to choose between sublimation and screen printing. In that case, this blog provides accurate details about both methods to help you make an informed decision.

Screen printing and sublimation are the most popular and widely used printing methods. The companies prefer these two methods to customize textile products. Screen printing suits small-batch clothes printing, whereas sublimation is relatively advanced and durable.

However, both printing methods use a type of stenciling technique. I have added more details to the topic, so keep reading and gather as much knowledge as possible.

What is Screen Printing?

Screen printing is also sometimes called silk printing since silk threads were originally used to make mesh screens. The process is very popular in the garment industry. It involves a mesh screen method, where ink passes through the mesh screen to leave the desired design on clothes.

Certain parts of the screen are blocked off to let the ink pass through the unblocked parts, forming a stencil. The ink that does pass through makes up the printed image.

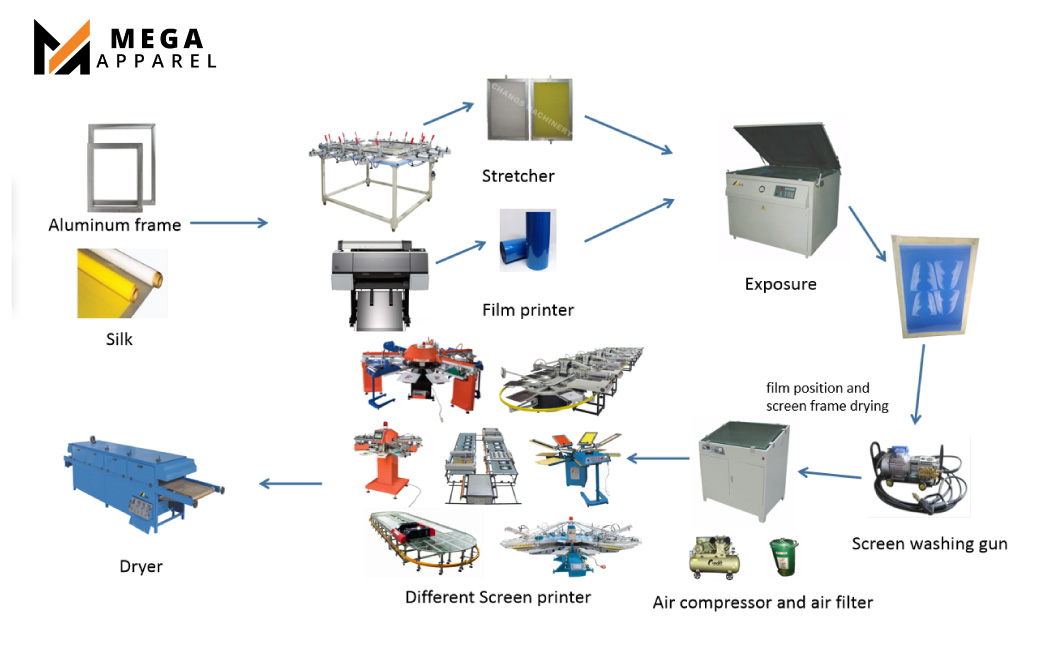

How Does Screen Printing Work?

- Screen printing is the most common type of commercial printing, and it uses a light-reactive emulsion to produce a significant stencil.

- The printer prints the designs onto a blank acetate film. Next comes the part of selecting the mesh screen suitable for the fabric’s texture and design. Then, the coating of the mesh screen with a light-sensitive emulsion takes place that solidifies when exposed to intense light.

- Then, the acetate sheet loaded with the design is placed onto the emulsion-coated screen to expose it to intense light. This light solidifies the emulsion and renders the parts covered by the design liquid. Consequently, it creates a “screen” or stencil with an exact imprint of the pattern or design, allowing the inks to penetrate through.

- Afterward, the screen is loaded onto the printing press. The item or fabric intended for printing is laid out flat on the printing board beneath the screen. Then, the ink is spread onto the top of the screen. The ink reaches the exposed areas of the stencil, transferring the design onto the object below.

What is Sublimation Printing?

Sublimation printing is a well-known printing method that uses pressure and heat to transfer dye onto textiles. It is usually the best option for printing on a larger scale or seam-to-seam. The process involves special inks and technology to print designs on various clothing products.

Sublimation printing requires applying heat and pressure to transfer patterns from sublimation paper onto various materials. The temperature typically ranges from 350 to 400 degrees. This process is straightforward, turning the solid ink particles into gas form.

How Does Sublimation Printing Work?

- This method of printing completely bypasses the liquid state and carries forward the transformation of solids into gasses. The bypassing of the ink drying phase distinguishes it from other traditional printing methods.

- A few items play a vital role in printing designs on the materials. A printer compatible with sublimation printing and capable of accepting sublimation ink cartridges is required.

- Heat pressing is applied to imprint designs onto materials. Since all the materials are unsuitable, users should be very picky about the fabrics. Either sublimation or copy paper (the transfer papers) is essential. Also, raster image processing (RIP) software for color correction is a must to enhance the printing process.

- Ceramic and Polyester are the two materials ideal for sublimation printing. However, this technique might be less effective in producing some designs or prints, especially those requiring intricate placement throughout the garment.

- This printing process requires synthetic fabrics since 100% cotton and other organic materials lack the pores to absorb ink. Therefore, these natural fabrics are unsuitable for the sublimation printing process.

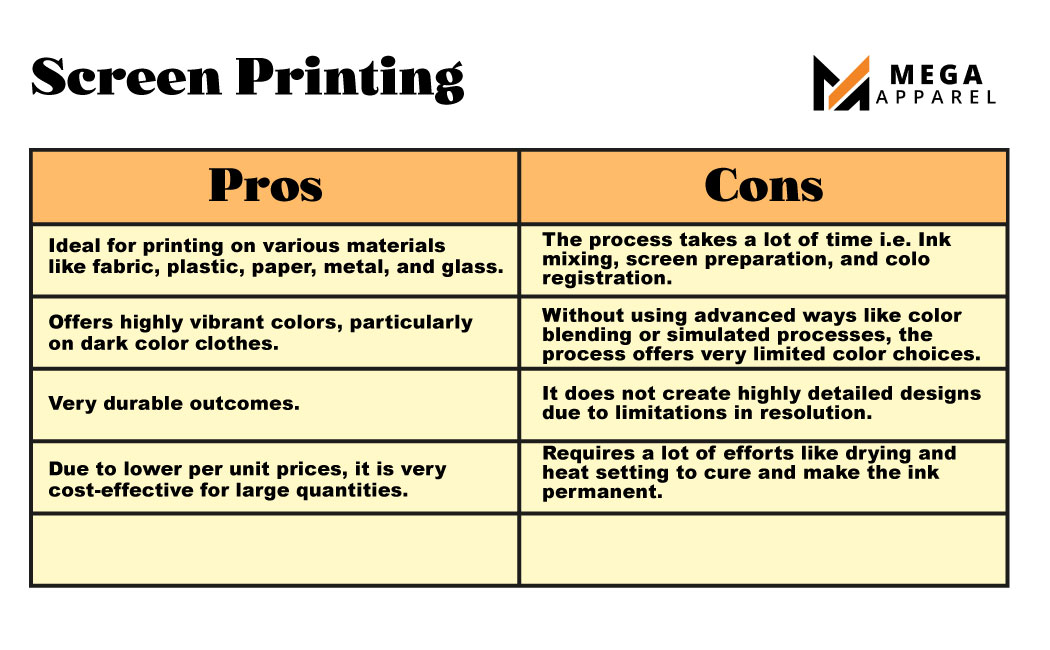

What are the Pros & Cons of Screen Printing?

Pros:

- Ideal for printing on various materials like fabric, plastic, paper, metal, and glass.

- It offers highly vibrant colors, particularly on dark-colored clothes.

- Very durable outcomes.

- Due to lower per-unit prices, it is very cost-effective for large quantities.

Cons:

- The process takes a lot of time, i.e., Ink mixing, screen preparation, and color registration.

- Without using advanced ways like color blending or simulated processes, the process offers very limited color choices.

- It needs to create more detailed designs due to limitations in resolution.

- It requires much effort, like drying and heat setting, to cure and make the ink permanent.

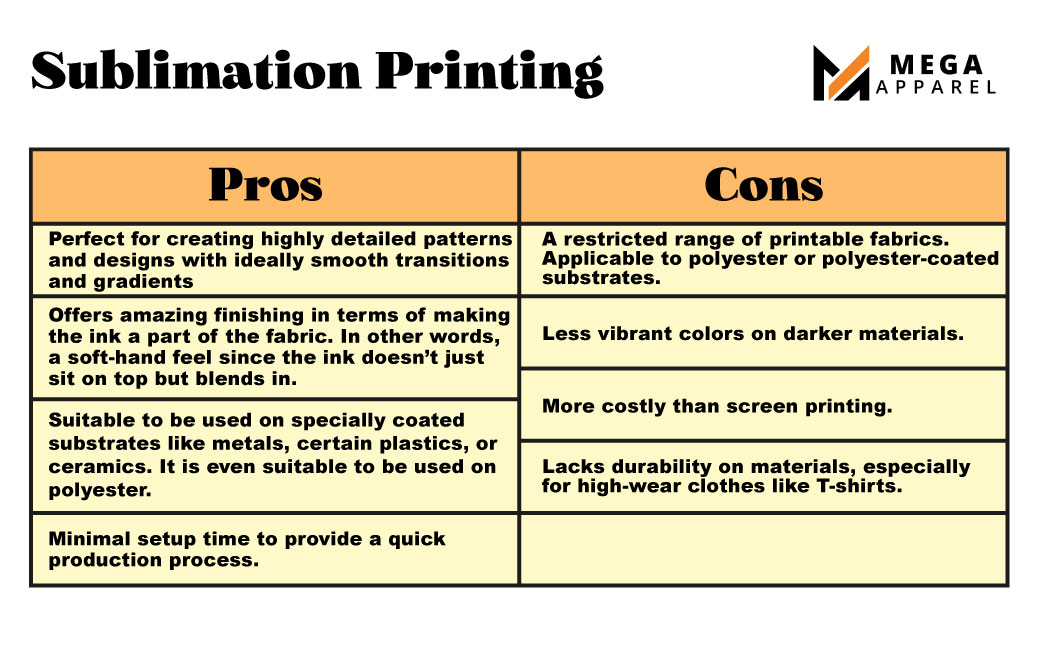

What are the Pros & Cons of Sublimation Printing?

Pros:

- Perfect for creating highly detailed patterns and designs with ideally smooth transitions and gradients.

- It offers amazing finishing in terms of making the ink a part of the fabric. In other words, it has a soft-hand feel since the ink doesn’t just sit on top but blends in.

- Suitable to be used on specially coated substrates like metals, certain plastics, or ceramics. It is even suitable for use on polyester.

- Minimal setup time to provide a quick production process.

Cons:

- A restricted range of printable fabrics. Applicable to polyester or polyester-coated materials.

- Less vibrant colors on darker materials.

- It is more costly than screen printing.

- It lacks durability in materials, especially for high-wear clothes like T-shirts.

Which Process is Better?

The primary difference between sublimation and screen printing lies within their different transactions with fabrics. Sublimation takes heat by which the print is imprinted directly onto the fabric, and as a result of this process, the feel of the fabric becomes soft and breathable. Using this procedure, one may effectively bleach non-absorbent synthetic materials, such as polyester, that have clear color.

However, screen printing uses an ink mesh of color to cover the fabric. This is why the fabric comes across with a slightly raised texture. Either way, the screen printing screens could apply designs to various materials, from cotton to darker tones.

Each method has its limitations and advantages. The decision is however up to you. Let’s see which process is more convincing to pick.

FAQs

How long does screen printing last?

Screen printing can be very durable and last for many years if handled with proper care.

Does sublimation last as long as screen printing?

The durability of sublimation printing depends on the fabric type. However, it can last a long time on polyester fabrics.

What is the longest-lasting t-shirt printing method?

Screen printing is usually the longest-lasting t-shirt printing method.

Take Our Help to Make the Right Decision

Mega Apparel is a model of perfection in manufacturing high-quality clothes using several printing methods. We offer both “Custom Screen Printing” and “Sublimation Printing” and can advise you regarding which method is better.

However, we will require certain information regarding your fabric choice, clothing product, design ideas, and so on to understand your requirements and give you the right solution.