A tricot fabric is a knitted material with outstanding structure and stretchability. The yarn is looped vertically along the length of the cloth during the warp knitting process. As a result, a sturdy, tightly knit fabric is produced that has a rough, ribbed look on one side and a smooth surface on the other.

Tricot fabric is well-known for its superior flexibility and recovery, which makes it perfect for clothing items that need to fit closely, such as lingerie, intimate apparel, sportswear, and swimwear. Although mixes with natural fibers like cotton or rayon are also popular, synthetic materials like polyester or nylon are used most frequently in their creation.

This material offers comfort and flexibility for a variety of uses since it is lightweight, breathable, and moisture-wicking. It is a well-liked option for a variety of sports and stylish apparel because of its adaptability, toughness, and capacity to hold shape.

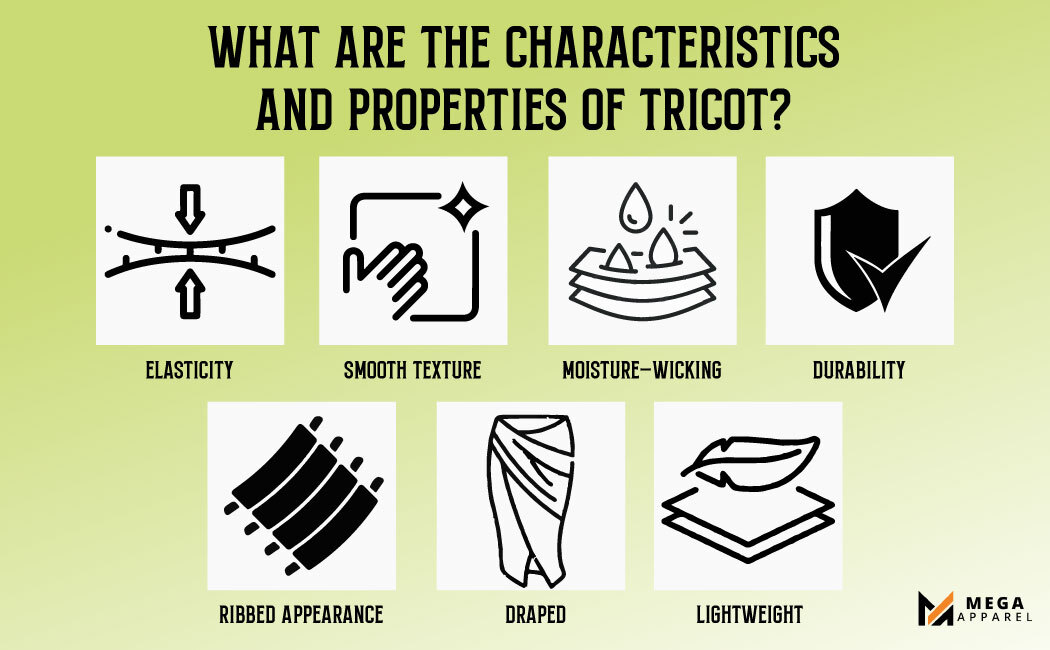

What Are The Characteristics and Properties of Tricot?

A versatile and durable wrap-knit fabric known for its unique characteristics and properties. Here are some key features:

1. Elasticity: Tricot fabric exhibits excellent elasticity and stretchability due to its knitted construction. It can stretch in both the warp (lengthwise) and weft (widthwise) directions, providing a comfortable and form-fitting feel.

2. Smooth texture: Tricot fabric has a smooth surface on one side, making it soft and comfortable against the skin. This smooth texture enhances the fabric’s aesthetic appeal and makes it suitable for garments that require a sleek finish.

3. Moisture-wicking: The superior moisture-wicking qualities of tricot fabric stem from its synthetic makeup. The cloth can dry more quickly as a result. It is utilized for swimwear and athletic apparel.

4. Durability: Tricot fabric is known for its durability and resistance to wear and tear. Its tightly knitted construction provides strength and resilience, allowing garments made from tricot fabric to withstand repeated washing and extended use.

5. Ribbed Appearance: On the reverse side, tricot fabric displays a ribbed or textured appearance, adding depth and dimension to the fabric. This ribbed structure contributes to the fabric’s stability and resilience.

6. Draped: The draping of the cloth is nice. It falls softly, following the contours of the body. This makes it appropriate in situations where a draped look is preferred.

7. Lightweight: Tricot fabrics are breathable, ideal for warmer climates or active use, and come in a range of weights.

What Are the Prominent Features and Uses of Tricot Fabrics?

Tricot fabric has two surfaces: one is smooth and feels warm and cozy on the skin, while the other is ribbed or textured, giving the cloth more depth and character. This fabric has natural moisture-wicking qualities that efficiently remove sweat from the body to keep the user dry and comfortable while engaging in physical activity.

Its strength and resilience ensure the fabric’s enduring capacity. The material is suitable for a variety of uses, such as linings for outerwear, lingerie, intimate garments, sportswear, and many more.

Let’s dive into the clothing products Tricot is suitable for:

Activewear

Tricot material is commonly used in activewear due to its elasticity, moisture-wicking properties, and comfort. It provides freedom of movement and performance benefits for athletes and fitness enthusiasts.

Swimwear

The smooth texture and durability of tricot material make it suitable for swimwear, offering comfort and support in water environments.

Lingerie and intimate apparel

Tricot material’s softness and luxurious feel make it ideal for lingerie and intimate apparel, providing comfort and elegance for everyday wear.

Outwear linings

Tricot fabric is often used as linings for outerwear garments, adding warmth, comfort, and durability to jackets and coats.

How to Make Tricot Fabric?

Tricot fabric is manufactured through a process called warp knitting, which involves inter-looping yarns in a lengthwise direction (the warp) to create the fabric.

Here’s a step-by-step overview of how tricot fabric is produced:

Step 1:

The process begins with the preparation of yarns. Yarns of desired fibers, such as polyester, nylon, or a blend of fibers, are wound onto cones or beams, ready for the knitting process.

Step 2:

The warp knitting machine, specifically designed for warp knitting, is set up with the necessary parameters, including gauge, needle selection, and stitch density, based on the desired characteristics of the tricot fabric.

Step 3:

In this step, the yarns are wound onto a warp beam in parallel to form the warp sheet. The number of yarns wound onto the warp beam corresponds to the width of the fabric and determines the density of the fabric.

Step 4:

The warp sheet is then transferred to the warp knitting machine, where it is mounted onto the warp beam. The warp sheet passes through the machine’s needle beds, which contain latch needles arranged in a vertical direction.

Step 5:

As the warp sheet moves through the machine, the latch needles interloop the yarns with additional yarn fed from the warp beam, creating a series of loops along the length of the fabric. This process forms the basis of the warp-knitted structure of tricot fabric.

Step 6:

Once the knitting process is complete, the tricot fabric may undergo various finishing processes, such as washing, dyeing, printing, or applying finishes for specific properties like moisture-wicking or flame resistance.

Step 7:

After finishing, the tricot fabric is inspected for quality control, ensuring that it meets the desired specifications and standards. Once approved, the fabric is rolled onto bolts or folded, ready for packaging and distribution to manufacturers for garment production.

Overall, the warp knitting process allows for the efficient production of tricot fabric with its characteristic elasticity, smooth texture, and stability, making it suitable for a wide range of applications in the apparel and textile industries.

What Are the Advantages of Tricot Fabric?

The prominent advantages of tricot fabric are:

- Tricot fabric is highly elastic, allowing it to stretch in both the warp and weft directions. This elasticity provides a comfortable and flexible fit.

- This fabric has inherent moisture-wicking properties, efficiently drawing moisture away from the body to keep the wearer dry and comfortable during physical activities.

- Tricot has a very smooth texture, offering a luxurious and soft feel against the skin.

- Its enhanced comfort level makes it ideal for various clothing products.

Do You Want Apparel Products Made With Tricot Material?

As mentioned in the above sections, tricot fabric holds great significance, and brands across the globe tend to have products made with such remarkable material. You don’t need to look anywhere else to acquire tricot clothes if you are among the people looking for durable clothes.

We are leading custom clothing manufacturers that source only high-quality fabrics to manufacture absolutely perfect clothes for you. To make it even easier for you, Mega Apparel is the manufacturing expert that can bring your dreams to life.

Conclusion

To sum up, tricot fabric has a number of beneficial qualities that make it a viable and adaptable option for a variety of textile industry applications. Its smooth texture improves comfort and visual attractiveness, while its elasticity offers a flexible and comfortable fit.

Moreover, tricot fabric’s natural ability to drain away moisture keeps users dry and comfortable while engaging in physical activity, which adds to its appeal in athletics and activewear. Its resilience also guarantees longevity and dependability, which makes it appropriate for a range of clothing and linings.

Tricot fabric continues to be a top option for producers and customers looking for high-quality, practical textiles for a range of applications because of its adaptability and capacity to provide comfort, flexibility, and performance.