The clothing industry is grooming and welcoming new trends every day, which is why clothing brands and manufacturers are grooming along with the innovations. Clothing manufacturing has become essential today since customers require quality and trendy products.

Either you are a brand, a startup, or even a new manufacturer with an interest in knowing about the role of manufacturers in the clothing market, this blog is going to help you gain knowledge about everything you need to know. This guide discusses the work, types, prominent roles, and ways to find clothing manufacturers.

What is a Clothing Manufacturer?

A clothing manufacturer creates apparel products using various techniques and technologies for vendors of clothes. An experienced clothing manufacturer is always loaded with new design ideas, cut and sew specialization, countless customization options, fabric sourcing methods, and lastly, flawless production of apparel.

How Do Clothing Manufacturers Work?

The work of manufacturers depends on various factors, such as the nature of the work, associated brands, types of products, and more. The role of production professionals in the apparel industry mostly revolves around catering to beginners, startups, and known brands. These new business founders approach suppliers to get either customized or pre-designed products in bulk.

If you are a brand and want to know how to start a clothing line, you can take advantage of a manufacturer’s help in getting customized clothes or understand the steps for any apparel they have already designed for you.

Other than that, they follow a simple process that starts with the planning of apparel design, tech packs and mockups, sampling, and ends with bulk production.

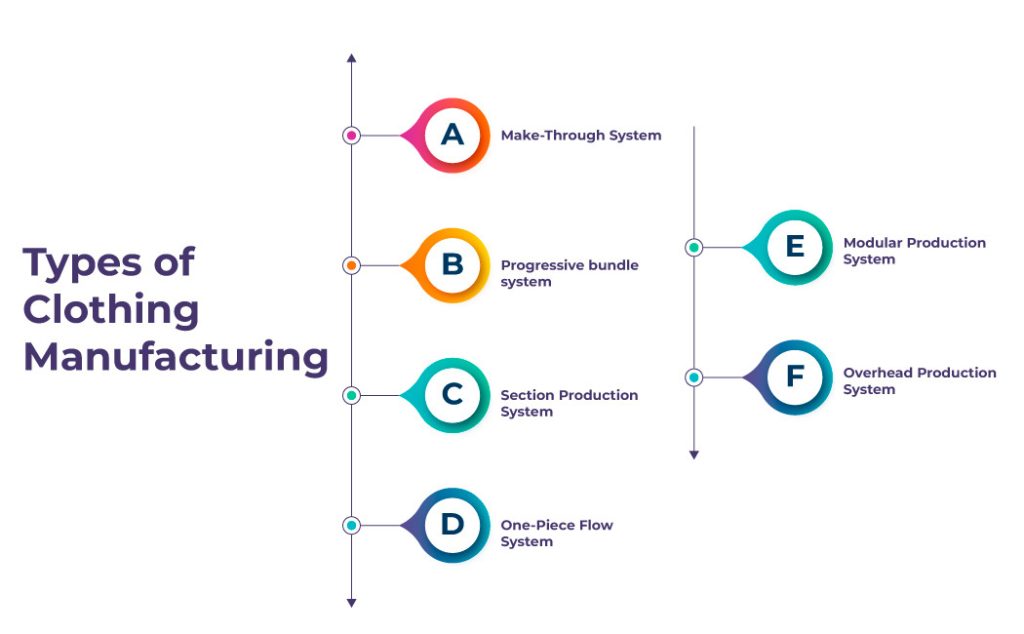

Types of Clothing Manufacturing

There are six types of apparel manufacturing, which are:

1. Make-Through System

The make-through system is one of the oldest ways of producing garments. This is a type of clothing manufacturing in which only one individual, the tailor, is responsible for all the tasks. The tailor creates patterns, does the cutting and sewing of garments, and completes everything related to production until the final product is formed and ready to be delivered.

A make-through system is usually used for small-scale production of clothes to cater to brands with minimum order quantity requirements or small-batch garment manufacturing.

One of the drawbacks of individual management is that any tailor managing all the operations on his or her own can take too much time to complete the products. It is costly for startups with low investments or budgets. Also, it requires a skilled set of hands and, thus, more money to spend.

2. Progressive bundle system

In a progressive bundle system, multiple operators work together to create a garment. They operate different machines. In other words, each operator is working on a different machine, and everyone has different tasks, which increases production and speed of work.

Each operator is skilled and experienced in the method, so the performance is enhanced and the end result is always good in terms of product finishing.

3. Section Production System

The selection production system is good for eradicating the line-balancing problem, which is a vivid case in the progressive bundle system. However, this method is a version of a progressive system.

This method is an innovative way of producing apparel, as the division of tailors into sections instead of lines makes the work happen quickly.

4. One-Piece Flow System

This method focuses on a single piece of product instead of a bundle. Different tailors work on different aspects of the piece. Every worker is supposed to work on only one task, which means that one particular tailor doesn’t need to be very skilled in other tasks.

In a one-piece flow system, the sewing machines are in linear order, so when one tailer is done with his or her work, the cloth passes on to the next one. Since every person has different roles and expertise, the process takes less time.

5. Modular Production System

In the modular production system, various workers form a group together and assign themselves different duties to finish an apparel product quickly and efficiently. A worker has multiple tasks, which means a particular person managing multiple tasks simultaneously needs to be skilled.

6. Overhead Production System

In an overhead production system, the garment or parts of it are hung over the hanger, which lies over the overhead rail. The hanger is used to contain all the components of a single apparel piece.

Differences between Clothing Manufacturers and Distributors

Clothing manufacturers and distributors are different on the basis of manufacturing clothes and supplying them to retailers and brands. Their role is prominent in the apparel industry, as both entities are closely related when it comes to producing finished products and distributing them among customers.

Clothing Manufacturers

The role of clothing manufacturers is to design, manufacture, and hand it over to the distributors, if they are not the ones delivering the products themselves to clients. In many cases, the manufacturers of apparel operate the distribution and delivery of clothes themselves.

They accept orders, and the in-house team of fashion designers, workers, and management put their heads together to complete the order and then deliver it to the doorstep of the customer.

Clothing Distributors

Once the manufacturers have finished the products, the clothing distributors play a crucial role in distributing or delivering them. The producers make clothes and then hand those over to the distributors to deliver the products to the destinations.

The role of distributors is simple. They take the finished products and give them to retailers, stores, or big brands. In some cases, they opt for a B2C model to cater to customers directly.

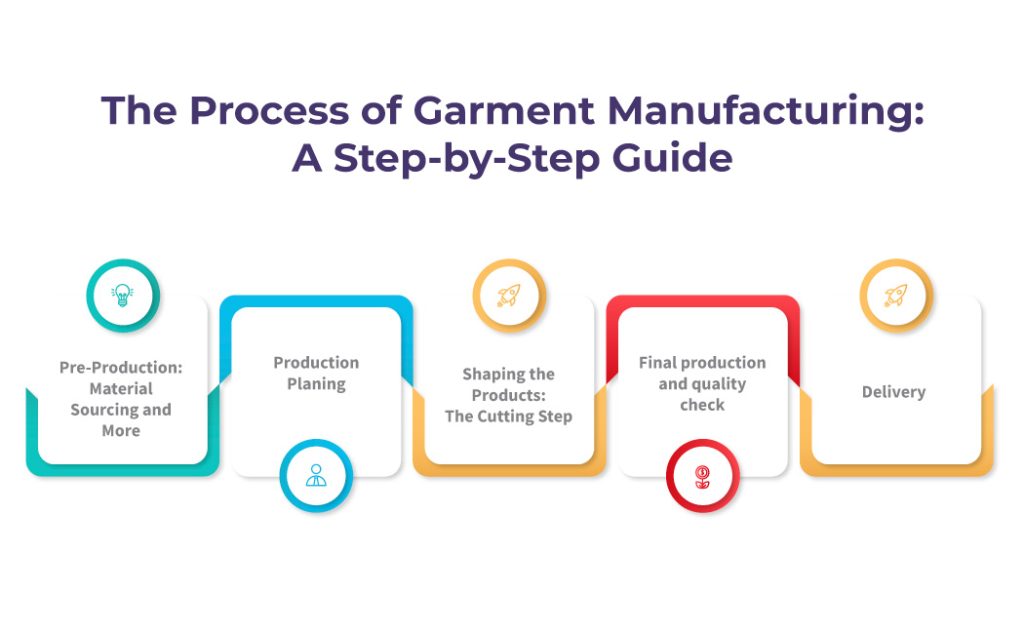

The Process of Garment Manufacturing: A Step-by-Step Guide

There are a few easy steps to manufacturing a garment with perfection.

Pre-Production: Material Sourcing and More

The pre-production step involves a few things, which are:

- Sourcing materials to be used in manufacturing the products. At this stage, the manufacturer sources quality fabric as per the customer’s requirements.

- The suppliers make patterns and designs according to the ideas presented by the customers. They show it to the clients in the form of a tech pack and mockup files, which contain all the measurements and a visual representation of the product.

- Then comes the sampling part, in which the manufacturers create a sample based on the designs and technical information in tech packs and mockups. Samples are a replica of the final product for customers to have a final look and recommend changes if there are any.

Production Planning

At this stage, the planning begins, in which the production team decides what needs to be done and how it should be done. The professionals check if everything they need to start bulk production is ready or not. If yes, they move on to the next step.

Shaping the Products: The Cutting Step

Since fabric is one of the most important components of clothes and seems to be an expensive one too, most customers require reasonable costs for manufacturing clothes, so they assume that manufacturers will not waste any of the material.

This is why, at the cutting stage, the manufacturers follow the designs and accurately cut the fabric to avoid any waste of material and money. Some manufacturers use old methods of cutting, like having multiple tailors manually shape the material. However, innovative producers use laser cutting or the latest machines to perform the task.

Final Production and Quality Check

The final production begins after making the necessary changes to the sample and cutting the fabric. Production takes place in a linear manner, in which the products are carefully produced.

After the production is complete, the quality of the finalized products is repeatedly checked in order to deliver the customer’s preferred apparel.

Delivery

The last step is delivering the products. Some manufacturers are associated with distributors, so they hand over the finished products to the distributors in order for them to deliver the items to retailers, brands, or stores. Other than that, many manufacturing companies carry out the delivery process themselves.

How to Find a Clothing Manufacturer

If you are wondering how to find a clothing manufacturer that can manage the effective production of your apparel, you need to figure out the ways through which your search becomes easy. Here are some easy and beneficial ways to find a reliable manufacturer.

- Trade shows and meetups

- Online Assistance

- Social media platforms

- Inquire about brands

- Industry directories

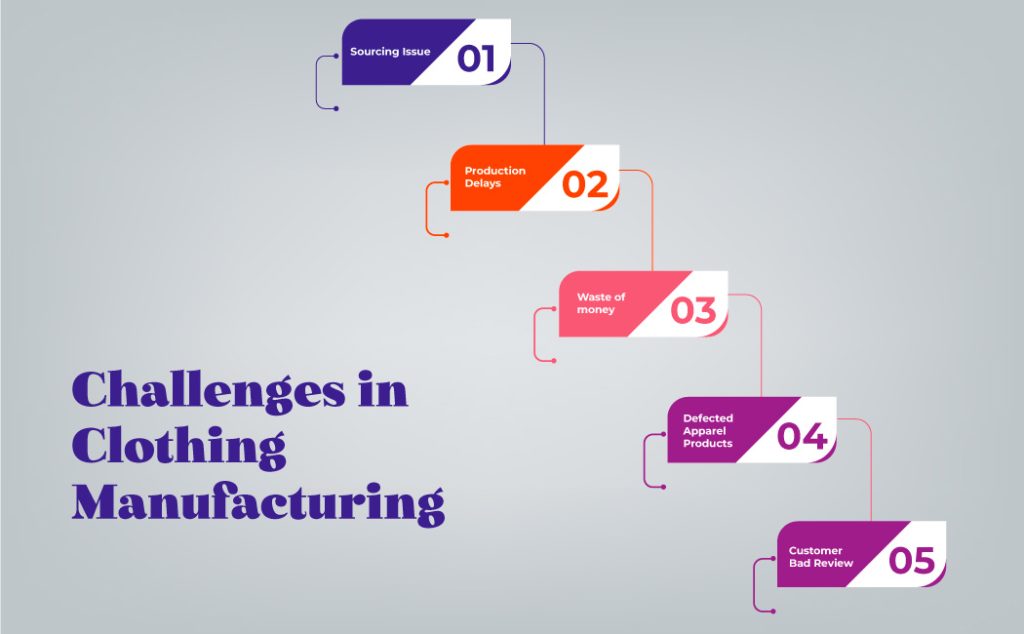

Challenges in Clothing Manufacturing

As the fashion apparel industry is rapidly growing, the consumption of goods is frequently increasing too. As innovative as it sounds, it comes with certain challenges in the manufacturing of clothing.

Sourcing Issue

At times, it becomes hard for manufacturers to source fabric for clothing due to a shortage of a certain type of material. Which leads to the late production and delivery of products. The biggest issue occurs when this setback turns out to be a factor in losing customers’ trust.

Production Delays

Production delay is the most basic yet highly problematic challenge for a manufacturer. There are a number of reasons for the delay in production.

- A manufacturing error causes the delay. If any operator of machines doesn’t do a fine job and ruins the material, then the production process takes a pause to rectify the error and begin again.

- Due to the wrong fabric, the production work has to take a break and get the right material, which leads to the slow production of garments.

- If the technology is outdated and machines have slow processing speeds, then manufacturers are bound to produce products at a slow pace.

- Lack of skills can cause some serious setbacks in production. At times, workers with less experience can cause certain errors, like wasting material while cutting, and then sourcing fabric again becomes necessary.

Waste of Money

The manufacturing process is not an easy task for many manufacturers since it requires perfection, accuracy, focus, and many other skills. Sometimes, if the production is not done correctly and causes defects in the final products, the customers usually ask for a redo, which results in the waste of a lot of money spent on the produced apparel.

Defected Apparel Products

Defects are considered among the most common and frequent challenges that occur during clothing manufacturing. There can be low-quality finishing, detached buttons, ripped patches, or a rough fabric texture. This leads to the production of those items of clothing all over again before delivering the bulk order.

Customer Bad Review

If any defect is neglected by the quality assurance team and the products get delivered, the customers won’t be happy and will express negative thoughts regarding the manufacturing company. This is never good for a company’s reputation or business.

Future Trends in Clothing Manufacturing

Future trends in clothing manufacturing refer to innovations in clothing production that will take place in the fashion apparel industry. Here are some of the trends that can offer promising outcomes in apparel manufacturing.

Advanced factory setups

Technology is getting more advanced day by day, and manufacturers will expect to adapt new ways of producing clothes with the help of cutting-edge technology. For example, digitizing operations and supply chains will help increase productivity.

The addition of technologically upgraded machines will ease up the manufacturing process and production of clothes.

Real-time feedback

The addition of real-time feedback will help in rapid data analysis, which is one of the price components of any production area. Real-time feedback will also help in analyzing and pinpointing the defects and flaws in the products. In doing so, erradicating the problems before they transform into something big can become easy.

Optimization of the Supply Chain

Optimization of the supply chain has become a necessity for the apparel industry in order for manufacturing companies to become competitive and stay one step ahead of the competition in the apparel market. Optimization will enhance the turnaround time and exclude unwanted delays in the delivery process.

Supply Chain Optimization will carry out in-house facilities, including design, fabric sourcing, production, and shipment services, in the same locality. In other words, making the company a one-stop solution

Addition of AI programs

Addition of artificial intelligence to analyze costs, production, customer data and feedback, sales, and risks. For example, the brand Tommy Hilfiger has already announced its association with IBM, an IT company, to design an AI program that will perform all these operations.

CRM Software

Customer Relationship Management (CRM) software is already in play to revolutionize the operations and management of manufacturing companies. CRM software helps in collecting and managing client data and organizing it for companies to enhance client dealing customer satisfaction protocols.

These are some of the trends. However, many other futuristic trends are imminent and will change the apparel industry completely in the near future.

Improved Infrastructures

Infrastructure plays a vital role in enhancing sales and production of apparel. In the coming future, the trend toward bigger, fancier, eco-friendly, robotic, and technologically advanced factories will take place.

This will improve the lives of workers, management, and production operations at the manufacturing companies.

Conclusion

Clothing manufacturing is a necessity in the garment industry since every startup, brand, supplier, and distributor are linked together in making and selling garments. Clothing businesses are grooming every day as the trends in fashion are witnessing major growth.

The clothing manufacturing process has opted for various ways to manufacture clothes. These ways help in different manufacturing purposes, such as for small-batch companies, which require a different method, and for bigger brands and manufacturing houses, which require some other method.

Finding a clothing manufacturer can be an easy task if you can follow some simple approaches. You can meet up with the companies at tradeshows, search for them on the internet, follow social media pages and communities to be a part of manufacturing company talks, ask brands to recommend good manufacturers, and lastly, check industry directories to get in contact with the manufacturers you want to work with.

The manufacturing process can have some problems that can result in production delays and negative feedback from customers. The defective pieces can cause setbacks in the production process and affect turnaround time. Other factors effecting the manufacturing process are already mentioned in the blog.

Manufacturing apparel is going to witness some great innovation in the near future, such as improved technology, machines, software, and soft infrastructure.